Remote Setting (Part 1)

John W. McCabe

The term remote setting describes the act of procurement

of competent bivalve larvae, especially oyster larvae, and inducing

their metamorphosis elsewhere.

Typically, a shellfish hatchery will raise bivalve larvae all

the way up to the eyed pediveliger stage (footed larvae

with "eye spots"). Such larvae are deemed ready to

attach temselves to some surface (i.e. deemed competent

or ready to set). Hatcheries will then sell some or all

of such larvae to shellfish growers who make necessary preparations

at their facilities to then take the larvae to the next developmental

stage. It's a win-win situation. The shellfish hatchery is relieved

of any further growing expense and risk. In turn, shellfish grower

are able to buy immense numbers of larvae at a modest price.

The larvae of several commercially important

bivalve species lend themselves to remote setting, most notably

oyster larvae and, to a much lesser extent, clam larvae. What

follows is a description of remote setting with Pacific (or Japanese)

oyster larvae (Crassostrea gigas). Remote setting of larvae

of other bivalve species can be (in most cases is) more demanding.

Although remote setting has been essential

in sustaining very high oyster production levels of Pacific oysters

on the U.S. and Canadian West Coast for decades, the outcome

of a remote setting effort by a grower is never predictable.

Even the most experienced grower faces uncertainties.

As such, remote setting adds to the fact that

nothing is, or ever has been, easy in the oyster business.

Since it all starts at a shellfish hatchery,

let's go there first.

Welcome to "Whoville"

A shellfish hatchery is a surreal place. Quadrillions of marine

organisms live here together, silently, in a space that typically

measures less than a soccer field. Most are invisible. Many millions

of microalgae can fit in a thimble and several million shellfish

larva can easily be carried in the palm of one's hand. Somehow,

Dr. Seuss' Whoville comes to my mind.

The low, monotonous whir of pumps harmonizes well with the hum

of lighting ballasts. Many water receptacles of varying shape

and size chime in discreetly with burbling sounds. The air tastes

moist and fresh and the temperature is comfortable. There are

no seasons here. Everything looks tidy and clean. To the casual

visitor, this world seems intriguing and somewhat surreal. Closer

study, however, exposes brutal realities. If someone turns off

the electrical supply, all of this "marine Whoville"

will very soon cease to exist. The threat of death by starvation,

disease, water quality issues (e.g. acidification, pollution)

or equipment malfunction is omnipresent - 24/7.

Surprisingly few humans operate this place. In a pinch, as few

as two or three competent people could work hard to keep this

huge menagerie of fragile plants and animals alive.

The underlying principle of a commercial shellfish hatchery is

simple: grow enough microalgae to feed enough bivalve larvae

that will turn into enough seed that will satisfy the requirements

of enough shellfish growers to generate enough hatchery income

to justify its existence. Clearly, the problem-word in that absurdly

long sentence is "enough". For example, what quantities

of what species of microalgae (aka phytoplankton) at what

stage of development are enough to make 1 billion oyster larvae

in an early stage of development happy? Some hatcheries grow

more than 20 different microalgae species to make sure that every

bivalve species raised is assured its special daily "phyto-cocktail".

What if thousands of liters of one microalgae species culture

suddenly "crash"? A "crash" describes sudden

death of microalgae cultures due to one or more reasons. It can

happen overnight (as I have learned the hard way with my small

algal cultures at home). A hatchery is usually prepared for such

crashes by growing enough microalge to offset  such

a loss. I could easily list twenty more risks in a hatchery operation,

some far greater than "phyto crashes". However, this

would lead us too far away from the topic of remote setting.

For now, suffice it to say that operating a shellfish hatchery

can be an exceedingly expensive and risky business.

such

a loss. I could easily list twenty more risks in a hatchery operation,

some far greater than "phyto crashes". However, this

would lead us too far away from the topic of remote setting.

For now, suffice it to say that operating a shellfish hatchery

can be an exceedingly expensive and risky business.

Inset image: Microalgae (or phytoplankton) growing containers

(so called reactors). The green algae in the foreground

is unknown to this writer (most algae species in shellfish hatcheries

are green). The golden-brown algae in the background is likely

a dense batch of the species Isochrysis galbana, certainly

a shellfish hatchery favorite. Click image to enlarge.

Shellfish hatcheries for American oysters (aka Eastern oysters;

C. virginica) date back to fledgling beginnings in the

1920s.

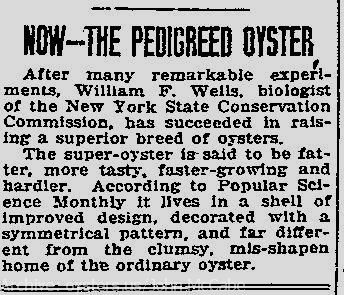

Inset

image: A news blurb touting The Pedigreed Oyster in the

Reading Eagle, March 18, 1927 (found in Google News Archive).

Inset

image: A news blurb touting The Pedigreed Oyster in the

Reading Eagle, March 18, 1927 (found in Google News Archive).

Pioneering work in successfully completing

oyster development from a larval to early post-larval state in

volume in a closed, controlled environment on a small scale can

principally be attributed to W. F. Wells (1920 ) and H. F. Prytherch (1924

) and H. F. Prytherch (1924 , 1937

, 1937 ). They built on and completed the remarkable research

of W. K. Brooks (1891

). They built on and completed the remarkable research

of W. K. Brooks (1891 )

and others. Large scale, reliable hatchery production of larval

to post-larval oysters (C. virginica) was not perfected

until the 1960s. Although Paul S. Galtsoff

)

and others. Large scale, reliable hatchery production of larval

to post-larval oysters (C. virginica) was not perfected

until the 1960s. Although Paul S. Galtsoff and Victor Loosanoof

and Victor Loosanoof are usually associated with this success,

there were numerous other naturalists that greatly contributed

as well. In the 1970s, shellfish hatcheries rapidly expanded

from the U.S. East Coast to also include the North-American West

Coast. Since then, many more shellfish hatcheries have been built

worldwide. In 1979, a detailed account of the history of shellfish

hatcheries titled Oyster Seed Hatcheries on the U.S. West

Coast: An Overview was furnished by J. W. Clark and R. D.

Langmo.

are usually associated with this success,

there were numerous other naturalists that greatly contributed

as well. In the 1970s, shellfish hatcheries rapidly expanded

from the U.S. East Coast to also include the North-American West

Coast. Since then, many more shellfish hatcheries have been built

worldwide. In 1979, a detailed account of the history of shellfish

hatcheries titled Oyster Seed Hatcheries on the U.S. West

Coast: An Overview was furnished by J. W. Clark and R. D.

Langmo.

Some large shellfish growers operate their

own hatcheries to insure their stocking needs and sell surplus

seed to other, typically smaller shellfish growers. Various universities

also maintain sophisticated hatchery operations. Although such

hatcheries usually focus on research and training, some are capable

of producing commercial quantities of seed.

Most growers either can't afford or don't care for the risks

involved in running a hatchery. However, a great number of North

American oyster growers, most notably on the U.S. and Canadian

West Coast, and also some clam growers, dare to short-circuit

the typical hatchery grow-out from sensitive bivalve larvae to

seed. They buy a hatchery's larvae in vast quantities and do

the rest themselves. In fact, U.S. West Coast demand for oyster

larvae has, for decades, been so great, that it can be feasible

to specialize a shellfish hatchery operation on oyster larvae.

The oldest and most famous hatchery of this type in the world

is the Whiskey Creek Shellfish Hatchery in Tillamook, Oregon,

USA. (view a short YouTube film by clicking HERE).

Spawning at the hatchery

As noted above, this example of remote setting focuses on Pacific

(or Japanese) oysters (C. gigas). Most shellfish hatcheries

keep so called brood-stock on hand. The term describes a relatively

small number of mature bivalves that have been selected as likely

to produce offspring with characteristics that  are desirable in the shellfish industry. The most

obvious such desires are rapid growth, good meat weight, sound

shells and a hardy constitution. It has long been known that

among bivalves, all things being equal, a few develop better

(from a subjective, commercial perspective) than others. Those

few individual bivalves are candidates for hatchery brood-stock.

Selective breeding of Pacific and Eastern oysters has been diligently

studied and applied for decades. In terms of the Pacific oyster,

the biggest name in brood-stock research on the North American

West Coast (and quite possibly the world) is the Hatfield Marine

Science Center, Oregon State University in Newport, Oregon, USA.

are desirable in the shellfish industry. The most

obvious such desires are rapid growth, good meat weight, sound

shells and a hardy constitution. It has long been known that

among bivalves, all things being equal, a few develop better

(from a subjective, commercial perspective) than others. Those

few individual bivalves are candidates for hatchery brood-stock.

Selective breeding of Pacific and Eastern oysters has been diligently

studied and applied for decades. In terms of the Pacific oyster,

the biggest name in brood-stock research on the North American

West Coast (and quite possibly the world) is the Hatfield Marine

Science Center, Oregon State University in Newport, Oregon, USA.

Unlike spawning in a natural setting, a hatchery does not depend

on environmentally favorable circumstances. Instead, it creates

such necessary circumstances whenever needed. Their brood-stock

spawns when directed to do so by the hatchery operators. There

are several ways to "convince" bivalves that the time

for spawning has come (e.g. sudden water temperature increase,

artificially introducing gametes into the water).

As described earlier in this report (see Four-Groups),

the probable outcome of an oyster-spawning event is fertilized

eggs and subsequent oyster larvae - ideally, many millions of

them. In hatcheries, these oyster larvae can take two routes.

Some will stay in the hatchery and will be reared further into

seed. Others will be sold, as mature larvae, directly to growers.

Inset image (click to enlarge): Oyster larvae rearing basins.

The contents look like huge batches of some brown bouillon soup.

Each basin contains several million larvae. Very close inspection

with the naked eye faintly reveals some movement.

Inset image (click to enlarge): Oyster larvae rearing basins.

The contents look like huge batches of some brown bouillon soup.

Each basin contains several million larvae. Very close inspection

with the naked eye faintly reveals some movement.

When it is time to fill an order from a

shellfish grower, the hatchery operators filter batches of fully

developed ("footed" and "eyed") oyster larvae

from the water in their rearing basins. There are various ways

to strain and count all these larvae. Even coffee filters have

been used at times in the straining process of bivalve larvae.

The larvae can then be centered on a small, porous fabric square

that sometimes looks as if cut from an ordinary white bed sheet.

The sides of the fabric square are then turned

up, bunched at the top and banded, thus rendering a larvae package

in the shape of a little ball. Such a ball with two million oyster

larvae measures about the size of a golf ball. Once this procedure

is done, time is of the essence. The larvae, now out of water,

must stay moist and cool. Depending on the grower's order, one

or several of these balls may have to be shipped promptly at

the same time. In a small, Styrofoam lined box, the larvae balls

are then bedded on all sides in moist paper towels or newspaper,

along with one or more small cooling packs. A reliable overnight

courier company then transports the larvae to the oyster grower.

Arrival

of Larvae at a Grower

Arrival

of Larvae at a Grower

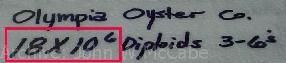

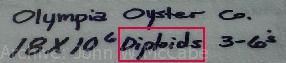

The inset image shows an example of the aforementioned shipping

box of larvae. In this case, it came from the Whiskey Creek Shellfish

Hatchery in the State of Oregon and was delivered promptly by

a Federal Express man at 1200 hours Pacific Standard Time at

the famed Olympia Oyster Company in the State of Washington.

It has been properly labeled on the lid of the Styrofoam box

liner with the buyer's name and the quantity of "18 x 10 , diploids,

3 - 6's". The first part of the label's lower text, highlighted

with a red square in the inset image, indicates the total amount

of larvae in this shipment. The timely Federal Express man can

now easily trump

, diploids,

3 - 6's". The first part of the label's lower text, highlighted

with a red square in the inset image, indicates the total amount

of larvae in this shipment. The timely Federal Express man can

now easily trump  any braggartry among his colleagues by validly claiming

to have, single-handedly, transported eighteen million live oysters.

any braggartry among his colleagues by validly claiming

to have, single-handedly, transported eighteen million live oysters.

Dips and Trips

Next on the labeling, the term diploids is used. Diploid

means, simply put, that these oyster larvae have, like humans,

two sets of chromosomes. From the  practical standpoint of a grower, the

diploid post-larval oysters (i.e. after metamorphosis) are likely

to grow at about the same rate that wild oysters would and, when

reaching maturity, would be able to reproduce. In moderate climates

with a fairly warm summer and fall, the oysters, when preparing

to spawn, would often have a "milky" consistency and

later, after spawning, their meat could seem sunken-in (a temporary

condition called spawned out). Although such meat conditions

are irrelevant to cooked oysters, many half-shell oyster lovers

do not much care for "milky" or "spawned out"

oysters.

practical standpoint of a grower, the

diploid post-larval oysters (i.e. after metamorphosis) are likely

to grow at about the same rate that wild oysters would and, when

reaching maturity, would be able to reproduce. In moderate climates

with a fairly warm summer and fall, the oysters, when preparing

to spawn, would often have a "milky" consistency and

later, after spawning, their meat could seem sunken-in (a temporary

condition called spawned out). Although such meat conditions

are irrelevant to cooked oysters, many half-shell oyster lovers

do not much care for "milky" or "spawned out"

oysters.

Had the label read triploid instead of diploid, the larvae

would have had, simply put, three sets of chromosomes instead

of two. From the practical standpoint of a grower, the triploid

oysters would grow at a considerably faster rate and 99% (or

more) of them would never reproduce. Instead of preparing to

spawn and turning milky, these oysters would just go right on

feeding without investing resources into the production of gametes.

Hence, triploids are unlikely to ever appear "milky"

or "spawned out".

Today, at least half of the C. gigas

larvae produced by shellfish hatcheries worldwide are triploid.

The reader might wonder why any grower would buy diploid larvae

and seed when triploids appear to be so commercially advantageous.

There are a number of reasons that could prompt a grower to choose

triploid oyster larvae or seed over diploid. Some growers appreciate

the potentially substantial natural sets the diploids can produce

in addition to the seed growing and remote setting a grower employs.

After all, it is a well known fact that, for millennia, the extraordinary

fecundity of oysters has been their recipe for survival. One

grower advised that juvenile triploids simply did not survive

on his tideland while diploids did. The principal of a large

U.S. West Coast shellfish growing company recently informed me

of excessively high mortality levels among his three to four

year old C. gigas triploids. Many growers in France have

blamed triploid oysters as the underlying reason for the recent

outbreak of a devastating, herpes-like disease among one to two

year old Pacific oysters in recent years. Some buyers who are

firm adherents of the tenets of organically grown food simply

don't want triploid oysters. They don't believe that mass production

of triploid larvae and seed is natural - and they are correct.

When, not if, oysters achieve a formal organic qualification,

I feel certain that triploid oysters will not be acceptable -

no more than oysters raised on tideland that has been sprayed

with pesticides (a long-standing practice of big oyster growers

on Willapa Bay in Washington State to kill indigenous mud shrimp).

Tennis

Balls Instead of Golf Balls

Tennis

Balls Instead of Golf Balls

A hatchery that sells oyster larvae can accommodate a

grower that practices remote setting by packing and shipping

various sizes of the aforementioned "larvae balls",

usually in one million larvae increments. By doing so, the hatchery

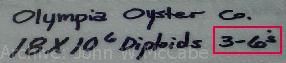

helps match a grower's remote setting tank size(s). In this example

case, the label reads "3 - 6s", thus indicating that

the shipping box holds three pouches (or "larvae balls")

of six million oyster larvae each. A ball of six million oyster

larvae measures about the size of a tennis ball.  Subsequently, the hatchery had to utilize

a piece of fabric measuring about 24 x 24 cm (~ 9.5 x 9.5 inches)

for each ball. The Olympia Oyster Company operates three large

remote setting tanks. Each tank requires six million larvae for

remote setting.

Subsequently, the hatchery had to utilize

a piece of fabric measuring about 24 x 24 cm (~ 9.5 x 9.5 inches)

for each ball. The Olympia Oyster Company operates three large

remote setting tanks. Each tank requires six million larvae for

remote setting.

William W. Budge

The methodology of shipping lots of little cloth pouches full

of millions of oyster larvae from a hatchery to far-away oyster

growers for remote setting is certainly a great invention, particularly

if one considers that this invention revolutionized U. S. West

Coast oyster cultivation back in the 1970s. I had often wondered

who came up with it.

For online searches of U.S. American patents

and trademarks, the United States Patent and Trademark Office

(http://www.uspto.gov) provides

several powerful search utilities. Most bountiful (and very fast)

patent searches can also be conducted via http://www.google.com/patents.

Thousands of oyster-related U. S. patents exist. The reading

of just a small fraction can easily keep an oyster aficionado

engaged for many hours on end. The mixture ranges from brilliant

ideas to blatant opportunism, devoid of any ingenuity. Someone

hoping to develop or further some new method or design that could

actually be of great value to others might grow discouraged when

trying to navigate this jungle of preexisting patent claims to

avoid potential infringement. Oftentimes, talented attorneys

have applied their formidable wordsmithing skills to the descriptive

language of patents, thereby expanding the coverage of patent

protection to the outermost limits of what might be called "interpretative

clarity". For example, in an excellent report on cultchless

oyster setting back in 1981, the researchers Herbert Hidu, Samuel

R. Chapman and David Dean devoted an interesting paragraph to

the discussion of the associated legal minefield. The paragraph

ends as follows:

"[…] It is literally impossible

to rear a cultchless seed oyster without infringing on someone's

broadly stated patent. Unfortunately, the

remaining problems with rearing cultchless oysters appear

not to be biological, but legal."

It so happens that one of the patents on the production of cultchless

oyster seed lamented in this paragraph, patent # 3,526,209, was

granted to the person who also was granted the unrelated patent

# 3,735,737: William W. Budge. This patent application was filed

Sept. 14, 1970, with the title "Method and Package for Storing

and Shipping Oyster Larvae". The patent describes almost

precisely today's modus operandi of shipping hatchery

larvae to oyster growers - and even includes a drawing of how

to fold the square of cloth around a little pile of oyster larvae

to produce the aforementioned "golf balls". On May

29, 1973, the patent was granted to William W. Budge from Hillsborough,

California. The assignee was Pacific Mariculture, Inc. in Pescadero,

California.

The results of my search of William W.

Budge (commonly called Bill Budge) and Pacific Mariculture suggest

that he was a brilliant and dedicated scientist who served as

the president of said company. Back in the 1960s and 70s, Pacific

Mariculture worked on the cutting edge of marine aquaculture,

primarily in the area of abalone cultivation and secondarily

in oyster cultivation. An online publication titled "ADVANCES

IN THE REMOTE SETTING OF OYSTER LARVAE", prepared by Gordon

and Bruce Jones, funded by the Aquaculture and Commercial Fisheries

Branch of the British Columbia (BC) Ministry of Agriculture and

Fisheries  ,

furnishes some details of Budge's pioneering work in remote setting.

In combination with his according U. S. patent # 3,735,737, I

find it reasonable to honor William W. Budge as the "Father

of Commercial Remote Setting of Oysters".

,

furnishes some details of Budge's pioneering work in remote setting.

In combination with his according U. S. patent # 3,735,737, I

find it reasonable to honor William W. Budge as the "Father

of Commercial Remote Setting of Oysters".

Part 1 Part 2

Footnotes located at the bottom of Part 2